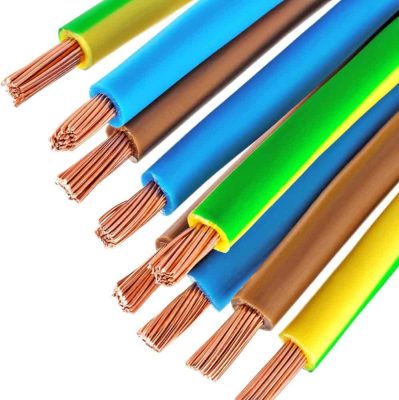

Testing electrical wires, especially those used in residential and industrial settings. It is crucial to ensure safety and compliance with electrical regulations.

The various tests that will be performed on electrical wires to assess their quality and safety are below, Alliance Ireland will help you with:

- Continuity Test: This test checks if there is an unbroken path for electric current along the wire. It is done using a multimeter to check for electrical continuity.

- Insulation Resistance Test: This test measures the resistance of the insulation material surrounding the wire. It ensures that the insulation is effective in preventing leakage of current and is usually done using a megohmmeter.

- Conductor Resistance Test: This test measures the resistance of the wire itself. It ensures that the wire has the correct electrical conductivity. Resistance is measured with a multimeter or ohmmeter.

- Voltage Drop Test: This test assesses the voltage drop along a wire under load. Excessive voltage drop can lead to inefficient electrical systems, overheating, and reduced performance.

- Short-Circuit Test: This test checks for short circuits or low-resistance connections in the wire. This can lead to electrical faults or fires. It’s performed using a multimeter.

- Dielectric Strength Test: This test checks the wire’s ability to withstand high voltage without breaking down. It is essential for insulating materials and is done using high-voltage test equipment.

- Bending and Flexibility Test: This test assesses the wire’s ability to withstand mechanical stress, such as bending and twisting, without damage.

- Temperature Rise Test: This test measures the temperature rise of the wire when it carries its rated current for a specified time. Excessive temperature rise can indicate overload or inadequate wire size.

- Flame and Fire Resistance Test: This test evaluates the wire’s resistance to flame and fire. It is particularly important for safety in case of a fire event.

- Corrosion Resistance Test: For wires used in corrosive environments, this test assesses their resistance to chemical corrosion.

- Ampacity Test: This test determines the maximum current-carrying capacity of the wire under specified conditions, ensuring that it can safely handle the load.

- Abrasion and Mechanical Durability Test: Wires may undergo testing for resistance to abrasion, impact, and other mechanical stresses to ensure they can withstand typical handling and installation conditions.

When testing electrical wires, it’s essential to follow safety protocols, use appropriate testing equipment, and adhere to industry standards and regulations. At Alliance Ireland our qualified electricians and engineers often perform these tests to ensure that electrical installations are safe, reliable, and compliant with local and national electrical codes.